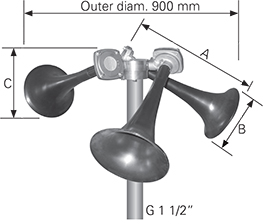

A pneumatic triple unit with flange for a 1 1/2” support pipe

A Special Sound

The tone of our well-known triple sound emitters is - to use an acoustical term - “complex”. That means a plurality of components in the frequency spectrum - in other words, many harmonical partial tones in addition to the fundamentals which are different for the three horns.

One advantage with this kind of sound is that its character is “alarming” and easily distinguished among other sounds.

A general demand on an alarm signals is the sound level being well above the noise level. With TYFON MKD 75/3 is experienced that the signal can be detected also in cases when such a condition is not prevailing.

Technical Data |

|---|

| Frequencies: | 350 + 370 + 390 Hz |

| Sound pressure level (30m): | 115 dB +/- 2 dB |

| Normal air consumption: (free air) | 20-30 l/s |

| Working pressure: (before apparatus) | 0.5 - 0.7 MPa (5 - 7 bar) |

| Weight: | 5 kg |

| Pipe dimensions: | Ø 15/12 mm |

| Dimensions in mm | |||

| Frequence | A | B | C |

|---|---|---|---|

| 350 Hz | 435 | Ø 200 | 370 |

| 370 Hz | 415 | Ø 200 | 360 |

| 390 Hz | 385 | Ø 200 | 340 |

Note: For a distinct code signalling, the pipe lengthbetween TYFON should not be more than 6 meter. Ref. no. 255 10 050

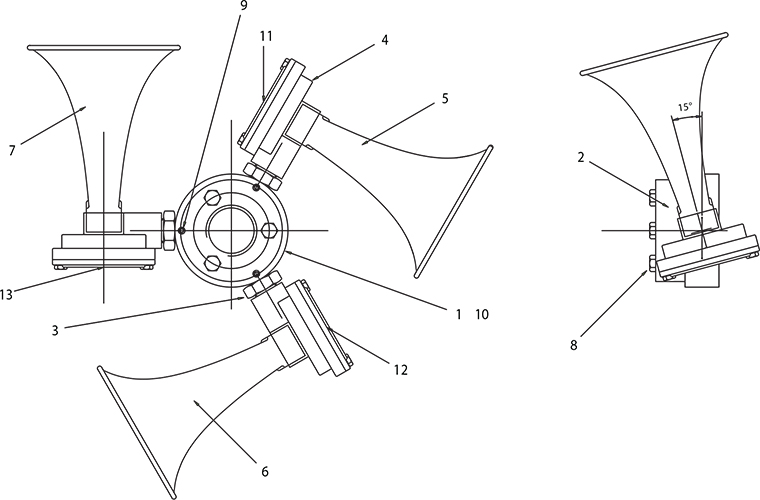

| Spare Parts | |||

|---|---|---|---|

| NO. | Name | Material | Ref. No. |

| 1 | Manifold | Brass | 21759560 |

| 2 | Flange | Brass | 21759959 |

| 3 | Screwing | Brass | 20864340 |

| 4 | Housing complete | Brass | 24510074 |

| 5 | Horn 350 Hz | Thermoplastic | 32170867 |

| 6 | Horn 370 Hz | Thermoplastic | 32170868 |

| 7 | Horn 390 Hz | Thermoplastic | 32170869 |

| 8 | Screw M6S M8 x 35 | Stainless steel | 20801125 |

| 9 | Screw MSK6 M6 x 8 | Stainless steel | 20801793 |

| 10 | Screwing GA 15-R ½” | Brass | 32300250 |

| 11 | Sign MKT75/350 | 21771027 | |

| 12 | Sign MKT75/370 | 21771028 | |

| 13 | Sign MKT75/390 | 21771029 | |

When ordering, please specify name and ref. no.

Installation

The sound emitter is made for a working pressure 0.5 – 0.7 Mpa directly at the inlet to the diaphragm housings. Consequently, some kind of pressure reduction has to be arranged for feeding the apparatus from common compressed air line. Normally, a choke plug does the job, inserted after the operating valve. The valve itself should have an orifice wider than the choke; otherwise the choke plug can be omitted. Valve TV 91, ½“ is preferred to be used for this apparatus. To avoid functional trouble, blow the supply pipe thoroughly clean before connection to the sound emitter.

Subject to alternation without notice.

A filter should be installed at the inlet of the operating valve to protect the signalling apparatus from dirt particles. A little oil or moisture in the air is harmless for the function. However, water pockets and sharp bends must be avoided.

Maintenance

The apparatus is manufactured of corrosion resistant materials and does not require painting. Diaphragm breakage never occurs at normal use unless the air pressure is considerably above upper limit. Adjustment of diaphragm or horn need never be made.